What Goes Into Planning Our YouTube Videos?

Over the past six years, RAM has produced more than 110 YouTube videos.

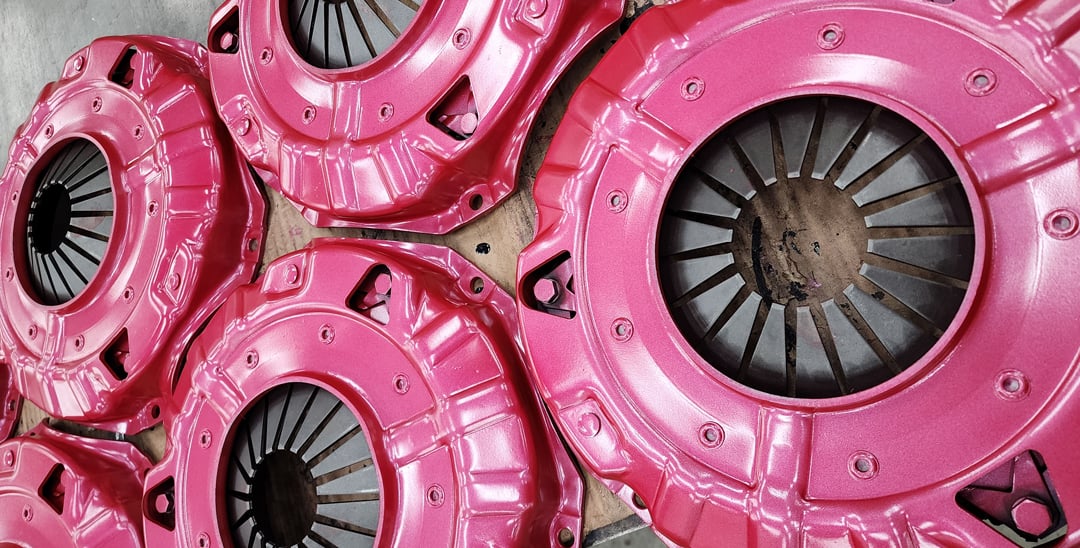

Topics range from commonly asked technical questions to new product introductions. We have even shot some pretty cool ‘hype’ videos featuring some of our customers’ race cars and showing off their cool street cars.

Answering Your Questions

How do we decide what we are going to produce each year? The easiest way is to look back at the most common tech questions we receive over the phone and via our RAM E-Tech form.

As the manufacturer of our parts, what seems to be perfectly obvious to us at RAM is not always so obvious to the customer. We look at topics like hydraulic bearing installation, which can generate questions like “What master cylinder do I need to use with my RAM hydraulic bearing?” or “How do I measure correctly to install my RAM hydraulic bearing?”

By addressing these questions through video, customers can now search our video library at night or on the weekend and, in many cases, find an immediate answer to their question.

Showing You the Latest Products

Introducing new products always makes for great videos. Previously, if you wanted to see what products were new, you had to attend an industry show like SEMA or PRI and visit every manufacturer’s booth.

If you couldn’t do that, you had to rely on news releases in the myriad of printed magazines that have since gone by the wayside. All of this could take months.

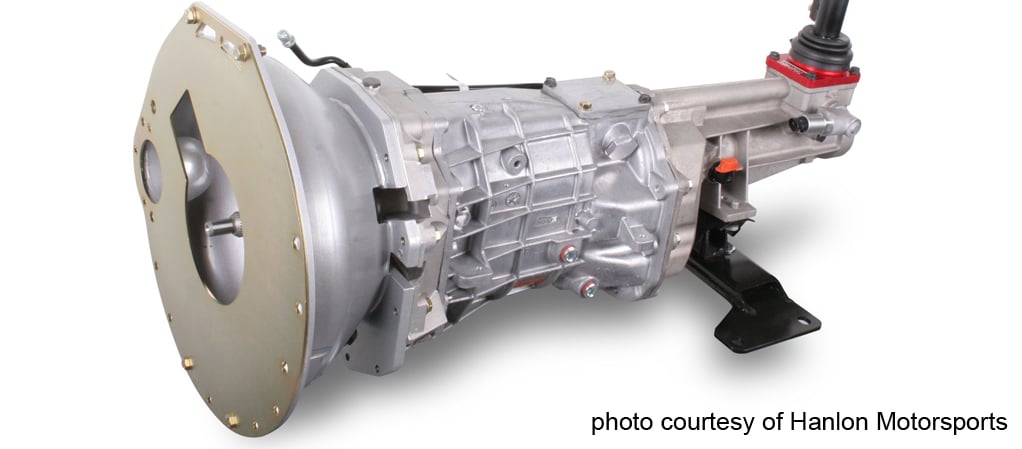

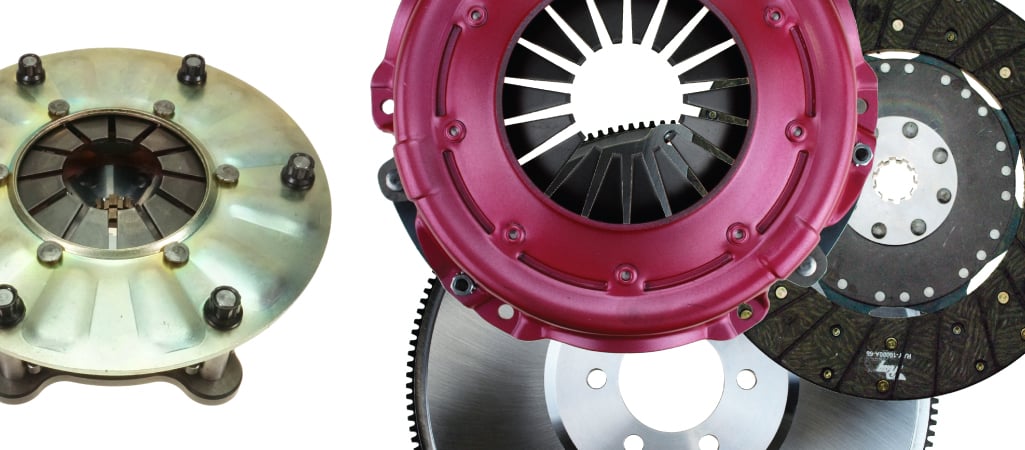

Now, if we have a new product today, there’s a good chance you will learn about it online by tomorrow from the comfort of your chair or on your phone! A perfect example is the new video describing the RAM Concept dual disc clutch systems and when and where to use each.

It Isn’t an Overnight Process

It’s fun and hard work to put these videos together. Typically, we start the process in the early fall by discussing topics we want to address for the coming year.

We develop a list of potential topics and then write outlines for each video. The copy is written from there, and a shot list is developed. After several months of bouncing ideas around, we settle in early December and begin to shoot. This usually takes several days, and often, follow-up clips must be created as we continue to refine the content.

Then, the hard part—sitting down and compiling the clips into a video that is both informative and, hopefully, somewhat entertaining.

One of our most enjoyable and popular projects was our four-part Industry Week series, which we created during the COVID lockdowns. At a time when people could not attend shows, we tried to bring the show to them in a fun, informative way. I encourage you to check these out if you haven’t yet!

We Need Your Help

We can’t always do it all ourselves, so we enlist a team of local video experts to shoot scenes like rolling car footage and beauty shots that they might produce into ‘hype’ videos or that we may incorporate into our in-house video work.

This is where you come in.

We’d love to hear from you regarding what videos and topics you would like to see – be it tech info on a certain product we haven’t covered, some specific installation procedure, or a technical issue you have run into in the past that you think might be helpful to our customers.

Feel free to email us at [email protected]. Also, be sure to check out our complete YouTube library!